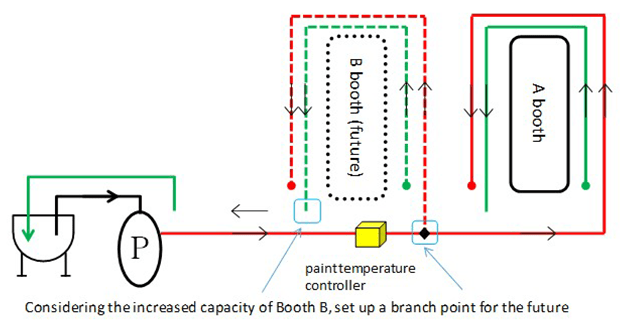

Parallel 2-pipe System

This system supplies paint to the paint equipment.

Compared to 2-pipe systems, this system can supply paint with minimal pressure difference at the outlet and change in paint temperature.

*Patented (combined with a paint temperature controller)

- Solve these issues

- ・Improvement of coating quality

・Reduction of equipment investment costs

Features

Reducing equipment investment costs

The parallel 2-pipe system minimizes the temperature difference at each paint outlet, making it possible to supply paint at a stable temperature.

As a result, the paint temperature controller (sub-heat exchanger), designed to reduce temperature differences, can be eliminated, and equipment investment costs can be reduced.

Compact size and expansion support

Compact piping routes can be proposed because unnecessary piping can be eliminated.

Furthermore, piping can be easily added, making it possible to support capacity expansion in the future.

Applications・Installation record

- Applications

- ・Automobile painting

・General painting

- Installation record

- ・Toyota Motor Corporation

・Daihatsu Motor Co., Ltd.

Contact us

Contact us below for inquiries, estimates, and technical information.

Paint and Application Systems Division, C.S. Sales Department

TEL:0565-24-4809

Email:cseigyo@trinityind.co.jp

Return to Paint and Application Systems Department|Technology and Products