Optimized Air Conditioning Control System T.E.G.A MPC

This control system combines MPC (model predictive control) and AI to significantly reduce power consumption in paint plants' air conditioning systems.

Very little data is required for learning; only about half a day's worth of operation data is needed to achieve sufficient performance. Additional online learning can further improve control performance.

(*Co-developed with Proxima Technology Inc.)

- Solve these issues

- ・Energy conservation

・Reduction of adjustment costs

Features

Outstanding control performance

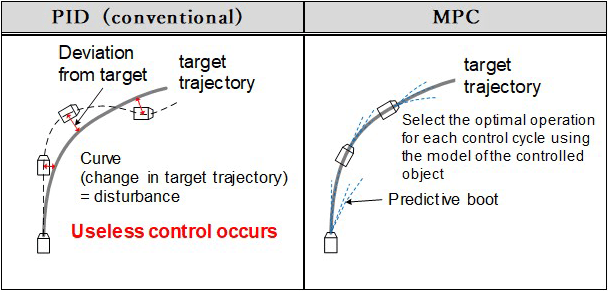

With MPC (model predictive control), outstanding control performance is achieved even for targets that are difficult to control with PID, such as targets with interferences between inputs, long idle times, and higher-order delays.

High energy savings through optimized control

MPC (model predictive control) enables optimized control that accounts for restrictions.

High energy-saving performance can be achieved even in complex air conditioning systems with many inputs and outputs by optimizing control with attention to energy conservation.

Reduction of adjustment costs

There is no need for time-consuming parameter adjustments through trial and error.

Using AI and machine learning, sufficient performance can be achieved by collecting about half a day's operation data.

In addition, online learning during operation allows the system to maintain high performance over a long period.

Applications

- Applications

- ・Automobile painting equipment

・General painting equipment

Contact us

Contact us below for inquiries, estimates, and technical information.

Paint and Application Systems Division, C.S. Sales Department

TEL:0565-24-4809

Email:cseigyo@trinityind.co.jp

Return to Paint and Application Systems Department|Technology and Products