iX Paint Equipment

The iX paint equipment maximizes the electrostatic force to suppress the airflow and achieve high paint deposition efficiency.

*Coating efficiency of 95% or more (ex.: automobile body)

- Solve these issues

- ・Reduction of CO₂ emissions

・Reduction of paint usage amount

・Reduction of booth cleaning frequency

・Reduction of paint equipment weight

Features

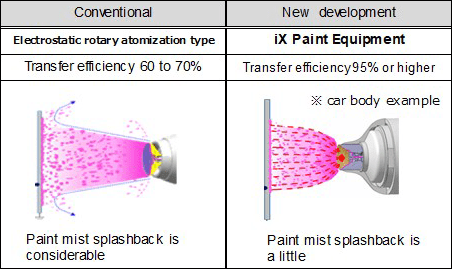

Achieving the world's highest standard of coating efficiency

By utilizing an electrostatic force in the coating process (atomizing, transporting, and applying paint), there is less paint mist bounce back compared to conventional air-spray coating machines, and a higher coating efficiency is achieved.

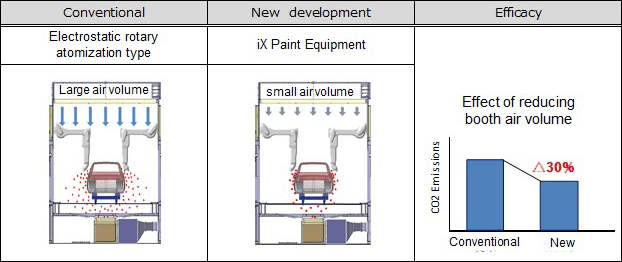

Saving energy with high coating efficiency

Since less paint mist bounces back, the amount of paint used can be reduced.

In addition, the booth airflow is also reduced, reducing CO₂ emissions and contributing to energy conservation.

Reducing cleaning costs

Minimal paint mist bounce keeps the booth cleaner inside and reduces the cleaning frequency. This leads to cost reductions in cleaning and wastewater treatment, etc.

Comparison image of paint condition *Example of automobile body paint

Electrostatic rotary atomization type New development :

iX Paint Equipment

Applications・Installation record

- Applications

- ・Automobile painting

・General painting (resin parts painting, etc.)

- Installation record

- ・Toyota Motor Corporation

・Toyota Motor East Japan, Inc.

・Toyota Motor Kyushu, Inc.

・Daihatsu Motor Co., Ltd.

・Kawasaki Motors, Ltd.

Contact us

Contact us below for inquiries, estimates, and technical information.

Paint and Application Systems Division, C.S. Sales Department

TEL:0565-24-4809

Email:cseigyo@trinityind.co.jp

Return to Paint and Application Systems Department|Technology and Products