Water transfer

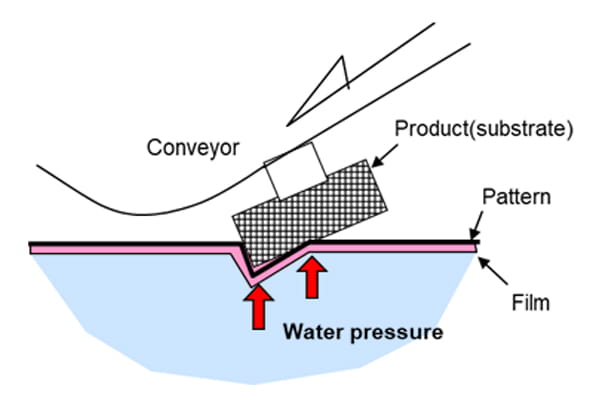

Water transfer is a process in which a water-soluble film with a printed pattern is floated on the water's surface and transferred.

This process can be used on curved surfaces and three-dimensional objects, which were conventionally not possible to print on. Patterns can also be transferred onto various materials, such as plastic, glass, and metal.

- Mechanism of water transfer

-

-

1.Transfer

The patterned film is ejected into the water tank, where it expands while guided by the tank's water flow and the guide chain until it reaches the transfer position. The expanded and softened film waits at the transfer position with the pattern side up. The transfer equipment presses the substrate against the film so that the pattern transfers.

-

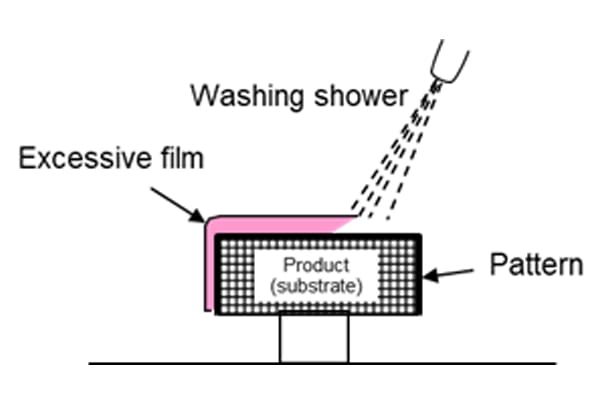

2.Film removal (de-filming)

The substrate onto which the pattern has been transferred is covered with excess film. The film is washed off in the next de-filming and cleaning process, leaving only the transferred pattern.

-

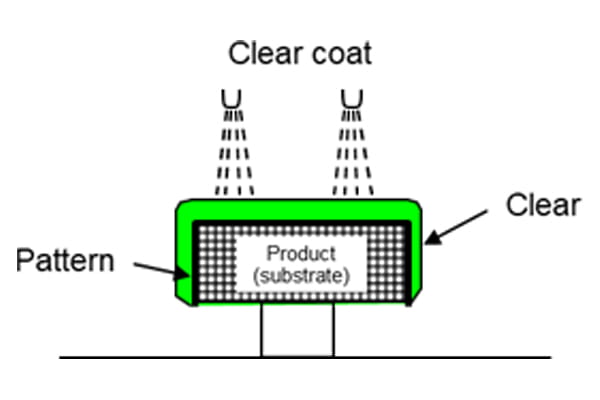

3.Clear coating (protective film)

After passing through a draining and drying oven, the substrate is sent to the coating process, where a clear coat is applied. It is dried and turned into a product.

-

Features

- ・Shape tracing

- ・Low cost

Available sizes

Max. 800 mm × 450 mm

Other sizes may be available. Please contact us for more information.

Patterns

Wood grain, stone grain, carbon, etc.

-

Wood grain (1) -

Wood grain (2) -

Stone grain (1) -

Stone grain (2) -

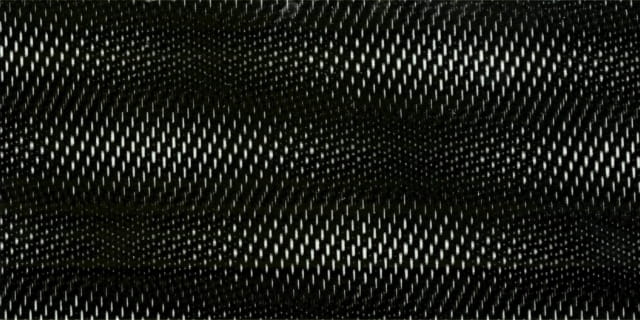

Carbon pattern -

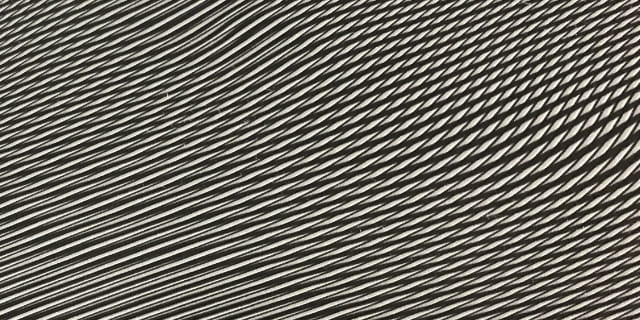

Inorganic pattern

Actual applications

Automobile parts

-

Door trim -

Console trim -

Steering wheel -

Navigator trim

Applications

This product can be used in the following areas.

- ・Automobile (interior/exterior)

- ・Household appliance

- ・Construction materials

Contact us

Contact us below for inquiries, estimates, and technical information.

Automotive Parts Division, Planning Department, Sales and Purchasing Group, Sales Section

TEL:0565-58-2381

FAX:0565-58-2317

Email:buhin-eigyo@trinityind.co.jp

Return to Automotive Parts Department | Technology and Products